An air knife system is a type of industrial technology used for various applications, primarily in manufacturing and processing industries. It utilizes a high-velocity stream of air to perform tasks such as cleaning, drying, cooling, and moving materials. The system typically consists of an air compressor, air knife, and associated components. Here’s an overview of the key aspects of an air knife system:

1. Components:

- Air Compressor: Provides a high-pressure air supply.

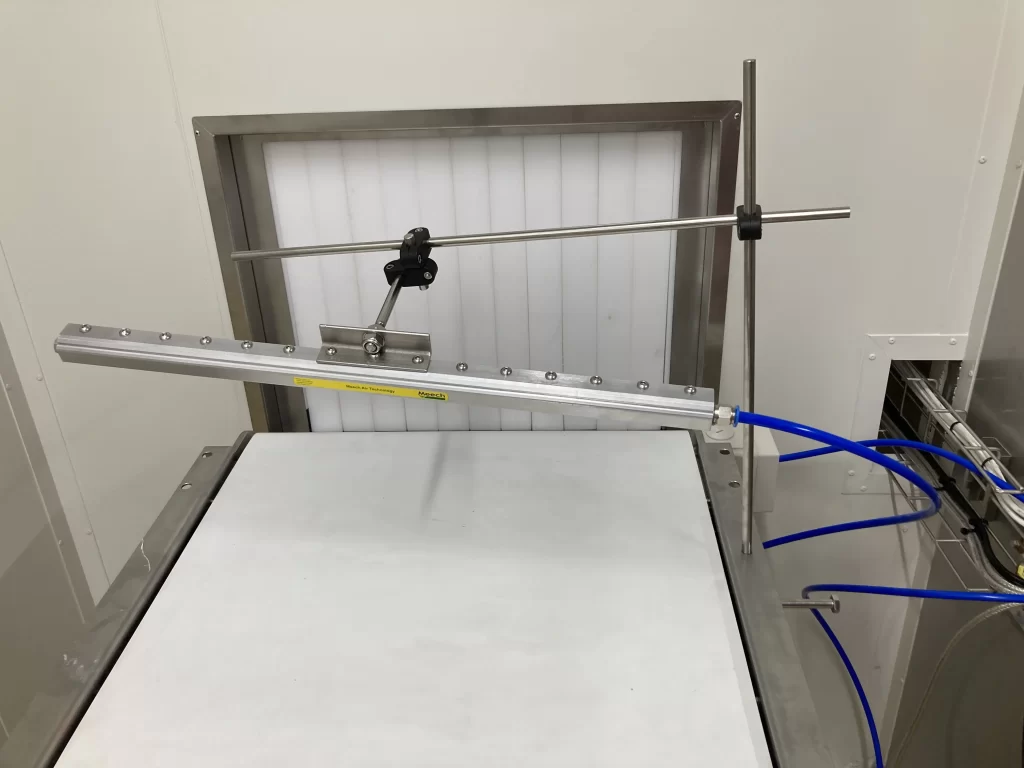

- Air Knife: A specially designed nozzle or series of nozzles that generate a laminar flow of high-velocity air.

- Air Filter/Regulator: Ensures the quality and pressure of the air supplied to the system.

- Mounting and Support Structure: Holds the air knife in place and facilitates its proper positioning for the desired application.

- Controller: Sensor actuated knife action to increase efficiency and cost savings is optional.

2. Applications:

- Drying: Commonly used to remove moisture or liquids from surfaces, such as products on a production line or bottles after washing.

- Cleaning: Effective in removing debris, dust, or contaminants from surfaces before or after manufacturing processes.

- Cooling: Used to cool products or materials quickly in industrial processes.

- Coating Control: Ensures uniform application and removal of excess coatings on products.

- Conveying: Air knives can be used to control the movement of materials on a production line.

3. Benefits:

- Energy Efficiency: Air knife systems are often more energy-efficient than traditional methods such as blowers or compressed air systems.

- Precision: Provides a controlled and targeted stream of air, allowing for precise application in various processes.

- Reduced Downtime: Faster drying or cooling times can contribute to increased production efficiency and reduced downtime.

- Cost Savings: Energy efficiency, reduced maintenance requirements, and improved process efficiency can result in cost savings over time.

4. Industries:

- Food and Beverage: Used for drying, cleaning, and cooling food products on production lines.

- Automotive: Applied in various manufacturing processes for drying, cleaning, and cooling automotive parts.

- Packaging: Ensures that packaging materials and products are free from contaminants and moisture.

- Printing: Used for drying ink on printed materials and preventing smudging.

- Metal Processing: Applied in metal cleaning and coating processes.

5. Considerations:

- Air Quality: Ensure that the air used in the system is clean and free from contaminants.

- Maintenance: Regular cleaning is essential to keep the system running efficiently.

- Customization: The design of the air knife system may need to be customized based on specific application requirements.

Air knife systems are versatile and can be adapted for various industrial applications, offering efficient and precise solutions for processes requiring drying, cleaning, cooling, or material movement.